Drier

General info about SIMAR- dryer controls

Two different types of controls are used in our drying systems. A compact control module is used in standard productions. We also offer an optional control module with a visualisation function for central dryers. This is based on S7 technology and is operated via a touch panel.

Both types are constructed exclusively out of components from well respected manufacturers.

Compact controls

Dryer operation via a 4-line screen with plaintext display in a choice of menu languages. User-friendly menu operation and easy setting of operating parameters. Plaintext display for error reports.

Integrated week-oriented autotimer for automatically switching the dryer on and off according to production requirements. Start-up monitoring for batch drying or dryer restart as standard feature.

Temperature monitoring using limit comparators, i.e. an alarm sounds when the air temperature target value is exceeded or not reached, adjustable according to the permissible tolerance ranges you select.

Indication of dew point temperature with an installed dew point measuring system.

Available for dryers with up to 4 installed supplementary heaters and 4 dry goods containers with installed load-dependent temperature regulator.

Position indicator for the individual motorised servo valves when load-dependent temperature regulator is installed.

Available with various interfaces for connecting to the central process guidance system.

S7 controls with touch panel (optional)

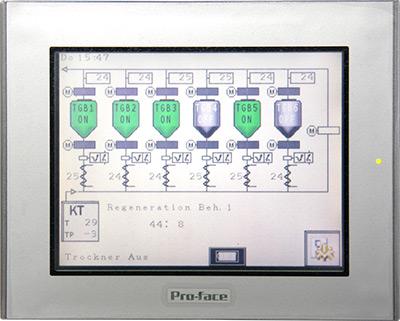

Operation of dryer controls via a touch screen.

Touch screen in various sizes for optimal representation of all information, even when a larger number of installed dry goods containers are being used.

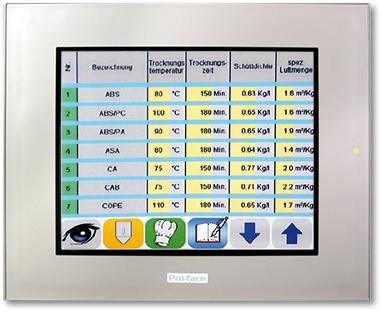

User-friendly menu operation, adjustment of all operating parameters and indication of error reports in a selection of menu languages.

Status indication and error reports in plaintext.

Historic memory for alarm alerts.

Visual depiction of the complete drying process in real time, i.e. a clear overview of all operating temperatures, position indicators for motorized salvo valves (optional, with load-dependent temperature regulator), fill level indicators for the corresponding dry goods containers (optional, with holding time controls) and graphic marking of defective components in the case of machine fault.

Integrated week-oriented autotimer for automatically switching the dryer on and off according to production requirements.

Indication of dew point temperature with an installed dew point measuring system Operating hour meter which enables pre-selection of maintenance intervals.

Available with various interfaces for connecting to the central process guidance systems.